The Industry at core.

We come from industry and are strongly connected to it. Our products enable more efficient and effective applications in a wide range of industries. Through state-of-the-art technology for actuators and sensors, we bring the standard further towards Industry 4.0.

In the development we include lifecycle cost and predictive maintenance concepts to offer our industrial customers maximum availability and reduction of follow-up costs.

Our region and the RACO family at heart.

Together and in partnership - that is our motto. That is why we consider it important to strengthen the region and the community. Therefore, we source most of our products only from the region.

Community and partnership are also our focus within the company. As a RACO family, we live a lively exchange among ourselves and strengthen our cohesion through regular activities.

The climate always present.

The climate is close to our hearts. That’s why we not only rely on short distances in our production, but also base all our actions on protecting the climate. We keep our supply chains as short as possible and contribute to climate protection with our CO2-neutral products.

In our production, we rely on the efficient use of renewable energies and when shipping our products, we use reusable packaging material.

With our products, the water stays clean.

Our products are also used in weirs and sluices, among other applications. We have developed a special, environmentally friendly drive concept for this purpose. In order to protect the water, we do not use hydraulic and lubricating fluids that could pollute the water, unlike hydraulic cylinders.

In particular, we have taken into account the hydraulic engineering conditions of use, the degree of protection of the components and the resistance to vibration and impact during development.

For a carefree life in the countryside.

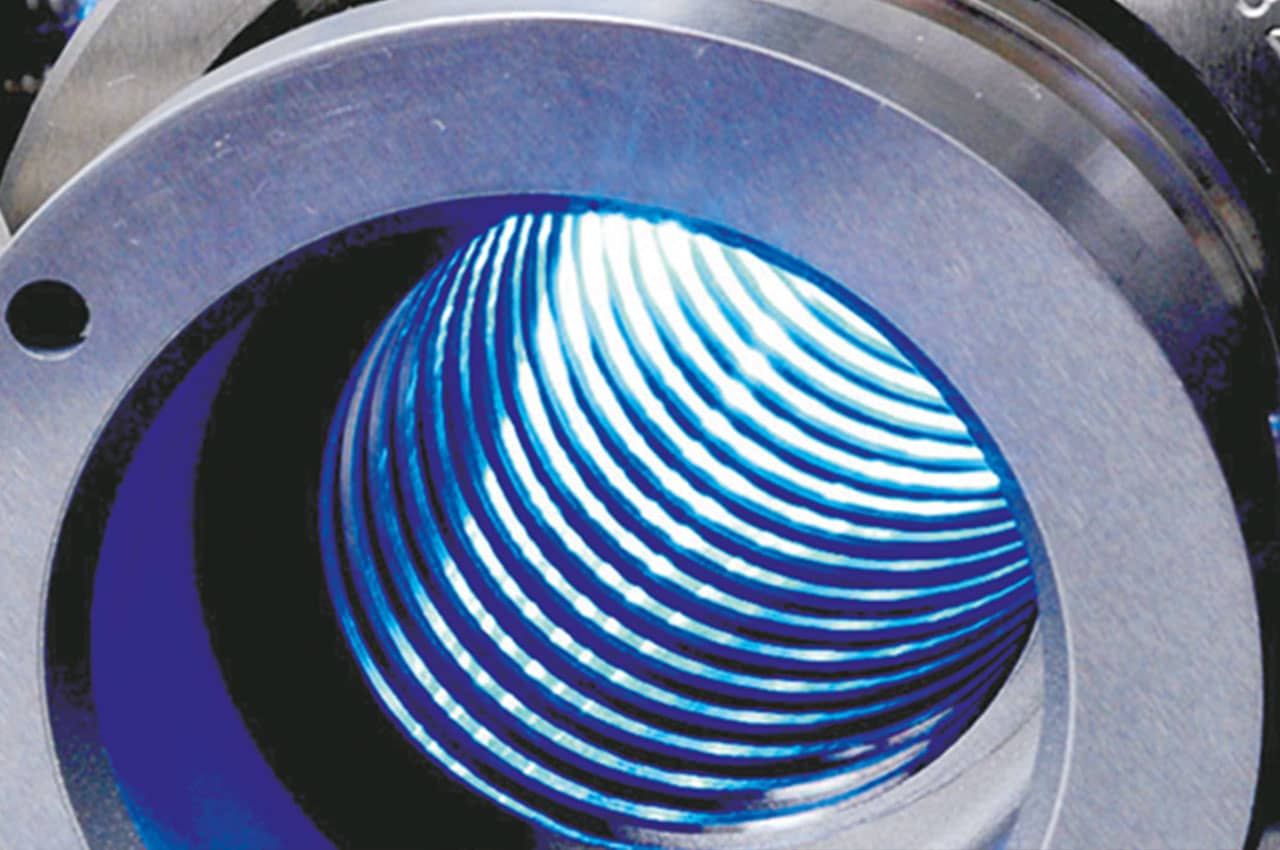

Our products are not only an environmentally friendly solution underwater, but also in any land application. Compared to hydraulic drives, our RACO electric actuators with ball screw offer a more resource-efficient and environmentally friendly alternative.

To live up to our claim, we also rely on sustainable solutions in our processes and operations.